MRO describes all steps and actions that are needed for the upkeep of a facility, the systems within the facility, and of course, the machines needed for the company’s main business output. It includes any action, including tests, measurements, replacements, and adjustments, that helps to maintain or restore products, machinery, tooling, or plants to their working conditions. Planned, predictive, preventative, and corrective maintenance are the main forms of overhaul.

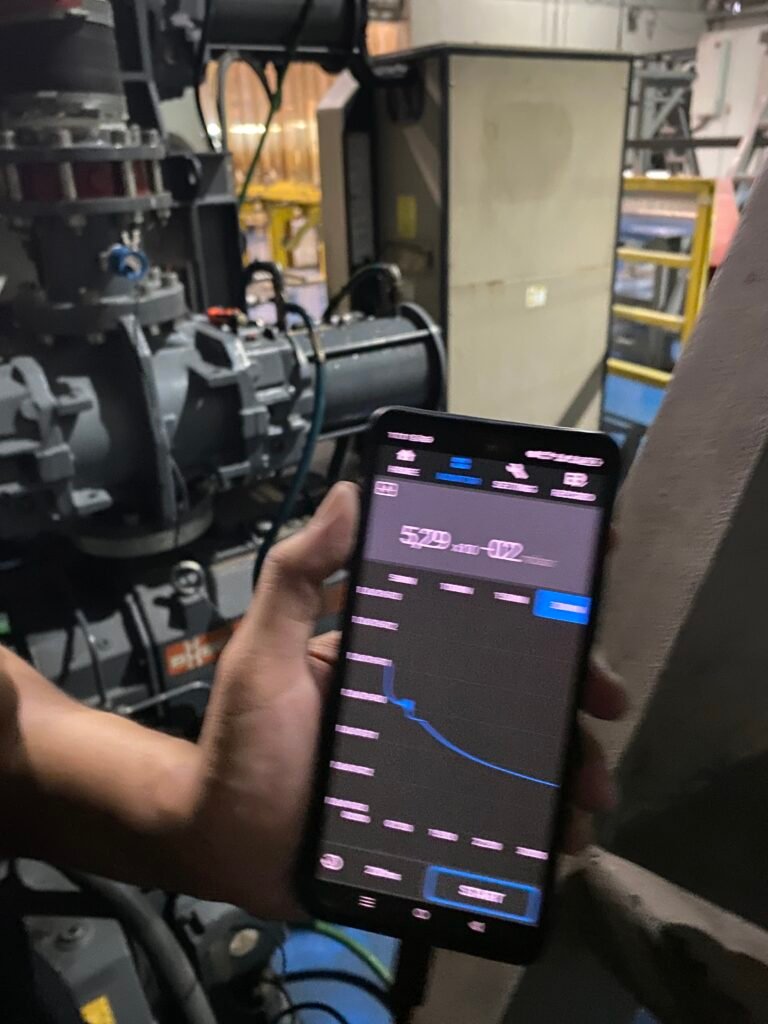

We are responsible for the integrity of parts, equipment, or infrastructure. To do so, we have to find and apply the right repair methods or contact the OEM to determine if the measured data exceeds the acceptance criteria. Unreliable data and unrepeatable results complicate your work, as do user-dependent measurements. How can you characterize damages and take corrective actions if the measured data on the same structure differs from one operator to another? More importantly, how can you make the right repair decision knowing that important operational and safety issues are often at stake?

Why Is MRO Important?

MRO has multiple benefits that your business can profit from if conducted properly:

Safety Benefits

If buildings, machines, and safety equipment are serviced at regular intervals, a safer work environment is created. Flaws and faults are uncovered through preventive maintenance in MRO before they can lead to workplace accidents.

Improved Workflow

Machines and other equipment can break or malfunction spontaneously and lead to workflow disruptions. These, in turn, can affect productivity. However, predictable wear and tear or minor flaws can often be detected with proper MRO and equipment management before they lead to bigger problems. This reduces downtime and ensures a smooth production process.

Financial Benefits

Maintenance, repair, and operations can seem like additional costs and efforts, but the benefits far outweigh the time and money spent on MRO and MRO software. Not only does it save time in the long run because downtime is reduced, but unexpected repair and the ensuing costs can be better predicted or even prevented through regular maintenance.

Predictability

Another benefit comes in the shape of predictability. If done correctly and regularly, MRO can help make your production process much more predictable. Scheduled repairs, maintenance appointments, and audits usually have a set date that companies can plan around and anticipate. It helps to adjust the production process that is much less frequently interrupted by unexpected repairs.